Description

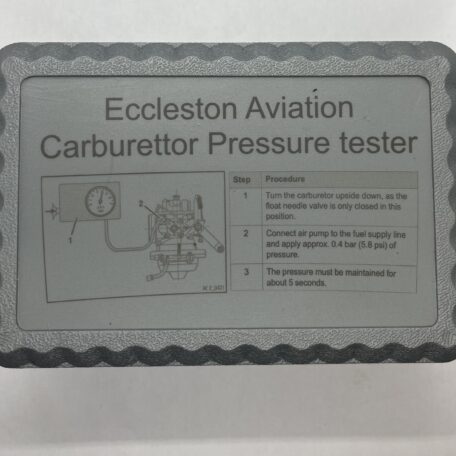

Carburettor Pressure Tester

Description

A precision tool used to test float needle valve sealing and diaphragm integrity in Bing carburettors fitted to Rotax 912 and 914 engines. This tester enables accurate leak detection during routine inspections or post-overhaul verification.

Kit Components

-

Low-pressure gauge with fine adjustment regulator (0–2 bar range)

-

Reinforced test hose with Bing-compatible carburettor fittings

-

Leak-release valve for safe depressurisation

-

Compact housing for bench or in-airframe testing

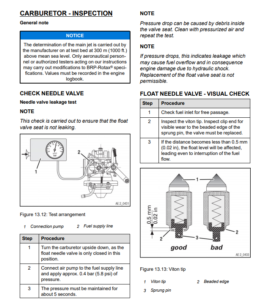

Needle Valve Leakage Test Procedure

Used during 100-hour and annual inspections to verify proper sealing of the float valve:

-

Disconnect the fuel supply from the carburettor.

-

Connect the pressure tester to the carburettor inlet.

-

Slowly apply 0.4 bar (5.8 psi) using the regulator.

-

Observe the pressure gauge for 5 seconds.

-

Stable pressure = needle valve is sealing correctly.

-

Pressure drop = possible dirt, wear, or float misalignment.

-

Important:

-

Pressure loss indicates leakage — clean the valve seat or inspect for worn components.

-

Release pressure before disconnecting the tester.